- SOLIDCAM FREE SOFTWARE DOWNLOAD HOW TO

- SOLIDCAM FREE SOFTWARE DOWNLOAD PRO

- SOLIDCAM FREE SOFTWARE DOWNLOAD WINDOWS 7

- SOLIDCAM FREE SOFTWARE DOWNLOAD SERIES

SOLIDCAM FREE SOFTWARE DOWNLOAD HOW TO

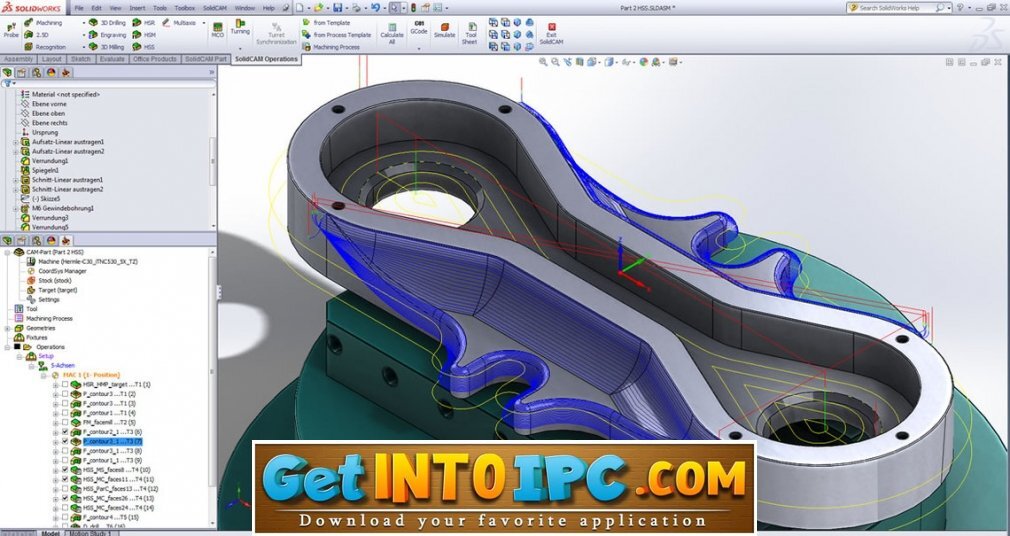

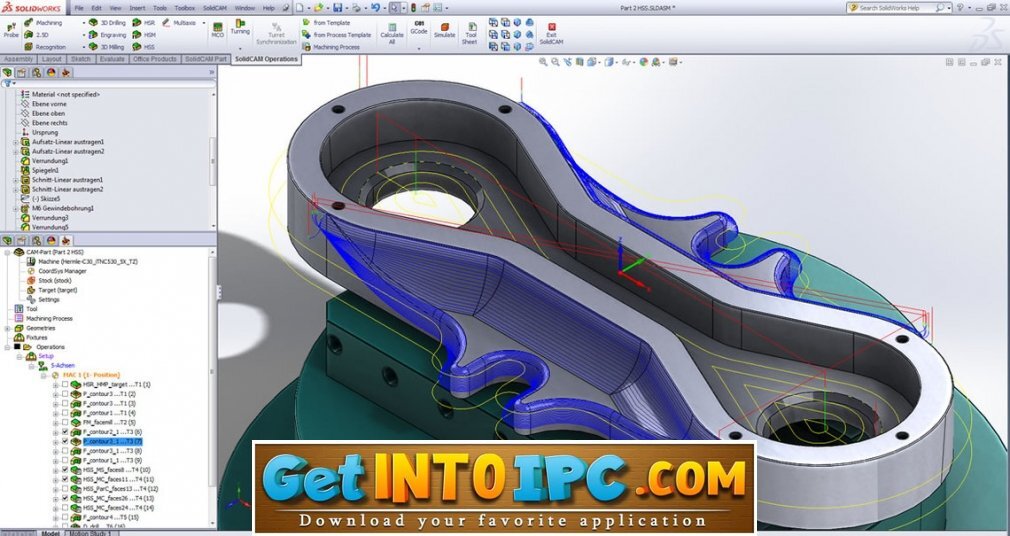

How to install SolidCAM 2020 for SolidWorks. SolidCAM 2020 for SolidWorks Free download. System requirements of SolidCAM 2020 for SolidWorks. Features of SolidCAM 2020 for SolidWorks. New PCIe M.2 drives are strongly recommended for use for the primary drive. Sata Controlled SSD (solid-state drive) is recommended at a minimum. All SOLIDWORKS Simulation products take advantage of multi-core and multi CPU architectures. SOLIDWORKS will take advantage of multi-core and multi CPU architectures up to 4 cores.

SOLIDCAM FREE SOFTWARE DOWNLOAD SERIES

The Intel i7 Generation 8 Coffee Lake series are the fastest CPUs today. Current generation Intel or AMD with SSE2 support processor – as fast as you can afford. For SOLIDWORKS 2019, the new performance pipeline requires Nvidia Quadro series cards Kepler, Maxwell, Pascal, and Volta that support OpenGL 4.5. While a certified video card is important SOLIDWORKS is a CPU-bound application, you’ll see more performance gains from a faster CPU. NVS pictures are not recommended they are 2D-only cards. Intergrated Intel HD graphics and gaming cards (Nvidia GeForce for example) are not certified and not recommended. Nvidia Quadro or AMD FirePro or AMD Radeon Pro.

Visit /sw/support/videocardtesting.html for a list of certified cards and drivers.32 GB or more – recommended for large assembly work and Simulation.Trimble Tekla Structures 2022 SP0 + Environments

SOLIDCAM FREE SOFTWARE DOWNLOAD PRO

SolidCAM 2021 SP4 HF1 for SOLIDWORKS / Standalone + DocsĪVEVA PRO / II Process Engineering 2021 圆4 IAR Embedded Workbench for ARM 9.20.4 + IAR Pack 2022

SOLIDCAM FREE SOFTWARE DOWNLOAD WINDOWS 7

Windows 7 SP1, 64-Bit ( End of Life: SW2020 SP5). Required system SOLIDWORKS 2020 System Requirements Operating System Provide physical processing parameters throughout the route. Wire EDM allows fixed and variable angle internal and external lines to be processed. Support for rotating tools that allow you to perform welding and drilling transfers to processing centers. Has many features, to automatically create programs for conversion and milling operations. Create a database of standard processes and once created, a parameter process can be reused in the future. Provide tools to identify and correct areas that were not troubled in the previous change phase. Axial machining using a three-dimensional surface or solid model. Provide a wide range of tools that can be used effectively to troubleshoot products with complex geometries such as prismatic components. Analytical machining of analytical surfaces. Various types of hole machining such as drilling, fastening, and drilling. Supports various strategies to address issues such as contouring, sampling, and channeling. Features of SolidCAM software and plugin:

Using a wide range of proposed lathe, milling, and electric discharge machining process strategies, the engineer can prepare the required set of CNC machining products in a short time. This system is a complete solution for the automation of metal production. SolidCAM CAD / CAM system developed by a new generation of SolidCAM (official distributor in Russia).

SolidCAM 2020 Documents and Training Materials.

SolidCAMCAD 2020 SP5 HF1 Standalone Multilingual 圆4.SolidCAM 2021 Documents and Training Materials.SolidCAMCAD 2021 SP4 HF1 Standalone Multilingual 圆4.Features of SolidCAM software and plugin:.

0 kommentar(er)

0 kommentar(er)